Eliminate production stoppages for sterilization, reduce the risk of contamination, and increase efficiency by incorporating Single-Use Molded Manifold Tubing Assemblies from AdvantaPure. Single Use Assemblies simplify cleaning validations—use once and discard.

Each system is custom made using AdvantaSil® platinum-cured, Class VI silicone tubing or reinforced hose or or AdvantaFlex® Class VI biopharmaceutical grade tubing to meet sealing and welding application requirements. Add fittings, stoppers and container closures, filters, sensors, bottles, labels, tracking options and now GORE® STA-PURE® Pump Tubing as the pump element.

Single use systems are not intended for implantation or continuous steam applications.

Platinum-cured silicone tubing (called APST), high pressure tubing (APHP), and braid-reinforced hose (APSH) are cleanroom manufactured by AdvantaPure for pharmaceutical and biopharm applications.

Platinum-cured silicone tubing (called APST), high pressure tubing (APHP), and braid-reinforced hose (APSH) are cleanroom manufactured by AdvantaPure for pharmaceutical and biopharm applications.

All three styles have undergone extensive physical, chemical, and biological testing and meet USP Class VI, FDA CFR 177.2600, ISO 10993, and European Pharmacopoeia 3.1.9 standards. Certified free of animal-derived ingredients.

APST size range: .030″ through 1″ I.D. (.76mm through 25.40mm I.D.) APHP size range: .125” through 1” I.D. (3.18mm through 25.40mm I.D.) APSH size range: .063″ through 1″ I.D. (1.59mm through 25.40mm I.D.)

AdvantaFlex® BioPharmaceutical Grade Tubing

AdvantaFlex® BioPharmaceutical Grade Tubing AdvantaFlex addresses the need for a flexible, translucent, sterilizable, heat sealable, weldable and moldable biopharmaceutical tubing without silicone oils. AdvantaFlex maintains its physical properties following sterilization processes and remains translucent for visible product flow.

AdvantaFlex addresses the need for a flexible, translucent, sterilizable, heat sealable, weldable and moldable biopharmaceutical tubing without silicone oils. AdvantaFlex maintains its physical properties following sterilization processes and remains translucent for visible product flow.

AdvantaFlex is ideal for aseptic tubing welds and helps eliminate aseptic connectors and multiple contact surfaces. The tubing is made from FDA-approved ingredients and meets various ISO and USP standards, including Class VI, as well as European Pharmacopoeia 3.2.2.1 standards. Certified free of animal-derived ingredients.

Size range: 1/8″ to 1″ I.D. (3.18mm to 25.40mm I.D.)

GORE STA-PURE Pump Tubing

GORE STA-PURE Pump TubingAdvantaPure is pleased to offer GORE STA-PURE Pump Tubing for your Single-Use Process biotech and pharmaceutical applications.

As experts in molded connections, AdvantaPure can now overmold GORE STA-PURE Pump Tubing into any manifold tubing assembly as its pump element. Overmolding reduces the risk of failure at the connection, decreases the chance of contamination, and helps prevent lost batches of costly pharmaceutical and biopharm product. Alternatively, connections may be made using barbed fittings and clamps.

NOTE: Assemblies that include GORE STA-PURE Pump Tubing cannot be gamma irradiated or be included in AdvantaPure’s validated sterility assurance program.

Size range: 1/16″ to 1″ I.D. (1.6mm to 25.40mm I.D.)

MORE ABOUT GORE STA-PURE PUMP TUBING

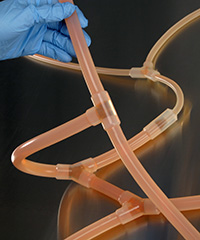

Molded Manifolds

Molded ManifoldsSingle-use Molded Manifolds provide a seamless transition between tubing and connections for a smooth, fluid contact surface with optimal flow. Molded connections include Y, T, cross, reducer, Tri-Clamp® and mini Tri-Clamp styles.

Made from AdvantaSil® silicone or AdvantaFlex® TPE, they allow for one contact material throughout the system. Additionally, GORE STA-PURE Pump Tubing can be integrated into silicone manifold assemblies as the pump element, providing longer production cycles. Connection sizes vary depending on style.

Size range: .1/8″ to 1″ I.D. (3.18mm to 25.40mm I.D.)

GORE® and STA-PURE® are trademarks of W. L. Gore & Associates.

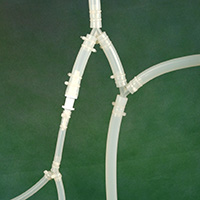

Tubing Sets

Tubing SetsIf you’re not sure molded manifolds are right for your application, let us manufacture your tubing sets (line sets). Assembled in ISO Class 7 clean rooms, they’re fabricated from tubing, fittings, clamps or cable ties, and accessories you specify.

Sizes to 1″ I.D.

Filling Assemblies

Filling AssembliesSterile molded filling assemblies from AdvantaPure continue the shift to Single-Use processes that save time and reduce the risk of cross contamination while increasing productivity between batches. Manufactured with a focus on quality, the assemblies can be quickly installed and operational in a fraction of time as compared to traditional systems used in pharmaceutical and biotech filling.

The multi-port Tri-Clamp® design reduces potential leak points, minimizes holdup volume and provides seamless flow.

Bioreactor Tubing Kits

Bioreactor Tubing KitsThe Single-Use kits are custom manufactured and assembled from a variety of components — tubing, filters, connectors — to meet your needs. Made from platinum-cured silicone or AdvantaFlex® biopharmaceutical grade TPE tubing, AdvantaPure’s Bioreactor Tubing Kits provide convenience and greater efficiency.

BioClosure® Systems – High Purity Container Closures

BioClosure® Systems – High Purity Container Closures AdvantaPure’s BioClosure Systems offer purity, secure seals, and versatility in design. Stoppers, caps, True Union and GL45 inserts, and other styles, available with or without tubing inserts, are manufactured from platinum-cured, Class VI silicone or AdvantaFlex biopharmaceutical TPE. Certified free of animal-derived ingredients.

AdvantaPure’s BioClosure Systems offer purity, secure seals, and versatility in design. Stoppers, caps, True Union and GL45 inserts, and other styles, available with or without tubing inserts, are manufactured from platinum-cured, Class VI silicone or AdvantaFlex biopharmaceutical TPE. Certified free of animal-derived ingredients.

MORE ABOUT BIOCLOSURE® HIGH PURITY CONTAINER CLOSURES

BioClosure System Assemblies

BioClosure System Assemblies Standardized configurations for media bottles, flasks and carboys using AdvantaFlex Biopharmaceutical Grade TPE tubing and molded components are available.

Standardized configurations for media bottles, flasks and carboys using AdvantaFlex Biopharmaceutical Grade TPE tubing and molded components are available.

| Connections |

Barbed Fittings

come in Y, T, elbow, and reducer styles. Materials include polypropylene, polyethylene, and PVDF.Size range: 1/8″ to 1″ hose I.D. (3.18mm to 25.40mm hose I.D.) Barbed Fittings

come in Y, T, elbow, and reducer styles. Materials include polypropylene, polyethylene, and PVDF.Size range: 1/8″ to 1″ hose I.D. (3.18mm to 25.40mm hose I.D.) |

Overmolded Ends

are available in mini Tri-Clamp styles in AdvantaFlex TPE for a smooth fluid path.

Size range: 1/8″ to 1/2″ tubing I.D. (3.18mm to 12.70mm tubing I.D.) Overmolded Ends

are available in mini Tri-Clamp styles in AdvantaFlex TPE for a smooth fluid path.

Size range: 1/8″ to 1/2″ tubing I.D. (3.18mm to 12.70mm tubing I.D.) |

Aseptic Connectors

reduce contamination risks and keep processing systems pure. Several easy-to-use styles are available. Aseptic Connectors

reduce contamination risks and keep processing systems pure. Several easy-to-use styles are available. |

|

|

| Filters |

Choose from a variety of styles, sizes, and manufacturers for your single use system. Choose from a variety of styles, sizes, and manufacturers for your single use system. |

| Sensors |

Single-Use in-line sensors offer real- time monitoring and control of critical processes. They eliminate the need for cleaning, maintenance and recalibration associated with traditional, reusable technologies. Choose from sensors for pressure, flow, temperature, conductivity, turbidity and UV absorbance. Single-Use in-line sensors offer real- time monitoring and control of critical processes. They eliminate the need for cleaning, maintenance and recalibration associated with traditional, reusable technologies. Choose from sensors for pressure, flow, temperature, conductivity, turbidity and UV absorbance. |

| Tubing-to-Fitting Attachments |

Oetiker® Clamps

provide a 360° seal with both a smooth inner and outer surface. Made from stainless steel, Oetiker clamps are lightweight and compact yet robust—only one is needed at each attachment.Size range: 5/32″ to 1-9/16″ nominal tubing O.D. Oetiker® Clamps

provide a 360° seal with both a smooth inner and outer surface. Made from stainless steel, Oetiker clamps are lightweight and compact yet robust—only one is needed at each attachment.Size range: 5/32″ to 1-9/16″ nominal tubing O.D. |

| Clamps |

Pinch Clamps

squeeze tubing closed anywhere along a line. One piece construction for sizes fit up to 3/4″ tubing O.D. (19.05mm tubing O.D.) Vise clamp for tubing 1″ and larger Pinch Clamps

squeeze tubing closed anywhere along a line. One piece construction for sizes fit up to 3/4″ tubing O.D. (19.05mm tubing O.D.) Vise clamp for tubing 1″ and larger |

Tri-Clamp® Connection Clamps

come in durable plastic and 304 stainless steel.

Size range: 1/2″ to 4″ (12.70mm to 101.60mm), depending on material Tri-Clamp® Connection Clamps

come in durable plastic and 304 stainless steel.

Size range: 1/2″ to 4″ (12.70mm to 101.60mm), depending on material |

BUILD YOUR SYSTEM FROM:

![]()

Sterile molded filling assemblies from AdvantaPure continue the shift to Single-Use processes that save time and reduce the risk of cross contamination while increasing productivity between batches. Assemblies can be quickly installed and operational in a fraction of time as compared to traditional systems used in pharmaceutical and biotech filling.

The multi-port Tri-Clamp® design reduces potential leak points, minimizes holdup volume and provides seamless flow.

Have your single use system gamma irradiated before it arrives at your location and save the additional inventorying, transportation costs, and transit time.

Bagged and labeled products are picked up from AdvantaPure’s facility and conveyed to a local gamma irradiation service provider. Using Cobalt 60 radiation, microorganisms and bacteria are destroyed while your single use system remains in its original packaging. Products are then returned to AdvantaPure for final inspection and shipment to your location.

A number of AdvantaPure’s silicone and AdvantaFlex products, particularly those designed for single use, are available with validated sterility assurance of 10-6 per ISO 11137 method VDmax. Contact us for more information at 1-888-755-4370.

| Home | Products | News & Events | About Us | Find a Distributor | Information Request | Contact Us | | Tubing & Hose | Fittings & Clamps | Single-Use Systems | Molded Products | Custom Products & Services | Hose Identification | | Product Videos | Legal Notices & Trademarks | Terms & Conditions of Sale | Privacy Policy | Feedback/Questions | Site Map |

AdvantaPure products are produced by NewAge® Industries, Inc., 145 James Way, Southampton, PA 18966 USA Phone: 215-526-2151 • 888-755-4370 (toll free US only); Fax: 215-526-2167 • 888-258-4293 (toll free US only); Email: info@www.advantapure.com

©2001-2021 NewAge® Industries, Inc. All rights reserved worldwide.