Phone: 1-888-755-4370 (toll free US only)

Phone: 1-215-526-2151 (worldwide) Email: info@www.advantapure.comSingle-Use Filling Assemblies

for Aseptic Fill and Finish Applications

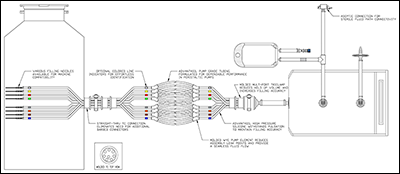

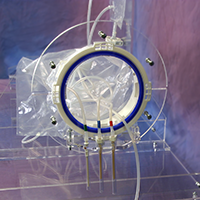

Single-Use molded filling assemblies from AdvantaPure® reduce the risk of cross contamination that can occur in traditional stainless steel systems and increase productivity between batches. Because every last drop of product matters in final fill applications, AdvantaPure filling assemblies are manufactured with a focus on quality and performance to ensure high product yields, free from contaminants. Single-Use filling assemblies allow for quick installations, offer flexibility in your manufacturing, reduce validation efforts, and lower environmental impact.

KEY FEATURES

- Single-Use filling assemblies minimize setup, installation, and cleaning time compared to stainless steel systems

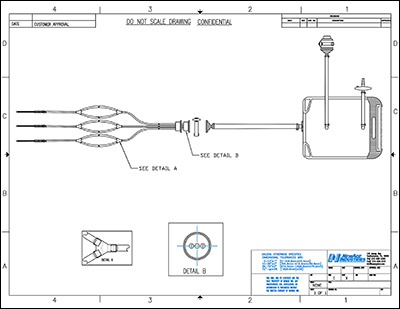

- Multiport Tri-Clamp® design reduces holdup volume, increases filling accuracy, and minimizes operator handling

- Molded junctions reduce the risk of leaks, entrapment, and contamination

- Transfer lines made from AdvantaSil® APHP high pressure silicone tubing reduce pulsation for more precise filling

- A variety of filling needles, aseptic connectors, and bags allows the configuration of systems as needed

- Multiple inline identification solutions, such as color coding, are available to make installation quicker and easier

- Available gamma irradiated and ready to install with validated sterility assurance of 10-6 per ISO 11137 method VDmax 25

- Documented quality control per ISO 9001:2015

- Documented lot traceable with identification on packaging

- Meets various ISO and USP standards, including USP Class VI

- Tubing validation and extractables portfolios available upon request

Choose your tubing material (high purity silicone, pump grade, high pressure, ultra low temperature, TPE), the number of lines, and additional components to configure your ideal system.

AdvantaPure's multiport Tri-Clamp® design reduces potential leak points and minimizes holdup volume – helps provide a continuous, steady flow.

Speak with AdvantaPure's experienced technical sales team and engineers to discuss your process requirements. Our team will work with you to develop a customized solution that meets your needs.

![]() Download a printable version of our Filling Assemblies brochure. Filling_Assemblies.pdf (1.8MB)

Download a printable version of our Filling Assemblies brochure. Filling_Assemblies.pdf (1.8MB)

Select from AdvantaFlex TPE Tubing or AdvantaSil APST Silicone Tubing

BioPharmaceutical Grade Tubing

BioPharmaceutical Grade Tubing

AdvantaFlex addresses the need for a sterilizable, moldable, weldable and heat sealable biopharmaceutical tubing without silicone oils. AdvantaFlex maintains its physical properties following sterilization processes, resists kinking, remains translucent for visible product flow and does not become gummy.

AdvantaFlex addresses the need for a sterilizable, moldable, weldable and heat sealable biopharmaceutical tubing without silicone oils. AdvantaFlex maintains its physical properties following sterilization processes, resists kinking, remains translucent for visible product flow and does not become gummy.

Silicone Tubing and Hose

Silicone Tubing and Hose

Low-volatile grade, platinum-cured silicone tubing is cleanroom produced for critical pharmaceutical applications. AdvantaSil products have undergone extensive physical, chemical, and biological testing and meet USP Class VI, FDA CFR 177.2600, ISO 10993 and other standards.

Low-volatile grade, platinum-cured silicone tubing is cleanroom produced for critical pharmaceutical applications. AdvantaSil products have undergone extensive physical, chemical, and biological testing and meet USP Class VI, FDA CFR 177.2600, ISO 10993 and other standards.

![]()

Single-Use filling assemblies allow for quick process changes and setup.

The multiport Tri-Clamp®, able to support up to ten ports, adds design flexibility for more complex systems.

GORE® STA-PURE® Pump Tubing

Series PCS; For Single-Use Peristaltic Pump Applications

As experts in molded connections, AdvantaPure can now overmold GORE STA-PURE Pump Tubing into a filling assembly as its pump element for extended performance in peristaltic pumps.