Phone: 1-888-755-4370 (toll free US only) Phone: 1-215-526-2151 (worldwide) Email: info@www.advantapure.com

CORONAVIRUS UPDATES

| AND WE’RE BACK February 18, 2022 |

| COVID cases caused by the omicron variant are on the decline here in the northeast U.S., and health officials are hopeful that the holiday surge has peaked. That doesn’t mean it’s over, however, and that precautions such as mask wearing, frequent hand washing, and social distancing can be discarded.

Our team members who had reverted to working from home during January will be continuing with those precautions now that we’re back in the office once again. We’re at our workstations, in our offices and cubicles, and ready to interact – safely – with our coworkers in Manufacturing, the Warehouse, Quality, and other areas. Want to see the latest on what’s happening at our expansion facility? See our Expansion update here. |

| ADAPTING – AGAIN – IN THE WORLD OF COVID January 24, 2022 |

| To help mitigate the spread of the omicron COVID-19 variant, we have returned to office personnel working from home when possible. Team members who can perform their tasks remotely, with the help of online meeting portals and other communication methods, are doing so for the foreseeable future. Most team members have been vaccinated against the virus, but we’ve taken this extra measure to help avoid breakthrough infections and to enable our staff and their families to remain healthy.

Workers in many departments, such as Manufacturing, Warehouse, Quality, and Engineering, continue to work in our buildings, because producing AdvantaSil® silicone tubing, AdvantaFlex® TPE tubing, and other tubing used for vaccine manufacture and therapeutic equipment (ventilators, for instance) is a necessary and essential function. Want to see the latest on what’s happening at our expansion facility? See our Expansion update here. |

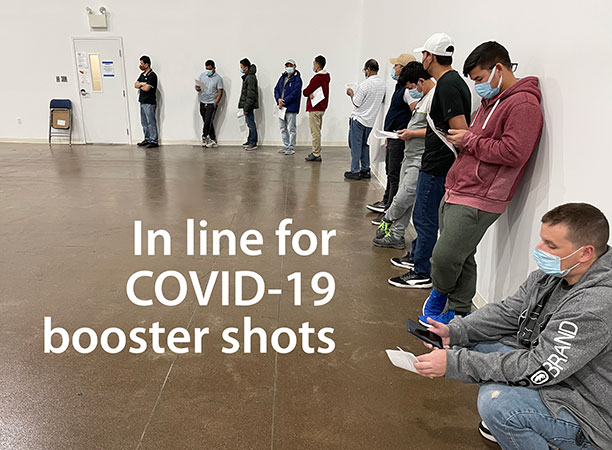

| ENSURING THAT WE STAY HEALTHY November 23, 2021 |

| To make it easier for team members to receive a vaccination against the seasonal flu, NewAge Industries AdvantaPure hosted a flu shot clinic a few weeks ago. Team members and their families were invited.

This past Friday, November 19, a COVID-19 booster shot was offered to team members. The company held an event for an initial COVID-19 vaccination for employees in May and offered the shot again in August. It’s all part of our goal to remain healthy so that we can continue to produce the fluid transfer products our customers need. Want to see the latest on what’s happening at our expansion facility? See our Expansion update here. |

| TESTING BEFORE RETURNING TO THE OFFICE November 02, 2021 |

| Several team members recently attended Interphex, a pharmaceutical industry trade show held in New York City. NYC has strict COVID-19 vaccination requirements, and team members were required to show proof of vaccination before entering a hotel, restaurant, and the Jacob K. Javits Convention Center where the show took place.

To help protect our fellow team members and families, everyone who attended the show was tested for the COVID-19 virus before returning to the office. Although all attendees were vaccinated, breakthrough infections are occurring, and we wanted to ensure that no one inadvertently brought the virus into our buildings. 93% of our staff is vaccinated against COVID-19, and the company will be offering on-site shots for the seasonal flu as well. Want to see the latest on what’s happening at our tubing expansion plant? See our Expansion update here. |

| 100% OF OUR MANUFACTURING TEAM IS VACCINATED October 01, 2021 |

| Although NewAge Industries does not have a COVID-19 vaccine mandate for employees, all our team members involved with the production of AdvantaSil® platinum-cured silicone tubing and braid-reinforced silicone hose, AdvantaFlex® TPE tubing, BioClosure® container closures, and Single-Use molding tubing assemblies are fully vaccinated against the disease.

Why does this matter? Because these are the people making tubing and assemblies that are used in the production of not only COVID-19 vaccines but the seasonal flu vaccine as well. According to the CDC’s website at cdc.gov, it is estimated that influenza accounted for an annual average of more than 18.5 million medical visits, over 566,000 hospitalizations, and 39,000 deaths over a recent three-year period.

NewAge’s tubing is also used in therapeutics to treat the flu and other diseases. Equipment such as ventilators, hospital beds, open heart surgery machines, Deep Vein Thrombosis (DVT) prevention apparatus, infectious waste containers, prosthetics, and oxygenators all contain tubing. A healthy and protected team means we can continue to manufacture these much-needed tubing products. We’re working diligently to increase our ability to produce more tubing. A clean room expansion at our Southampton headquarters was recently completed, and renovations continue at our Warrington operations. See our Expansion update here. |

| NEWAGE INDUSTRIES’ IMPLEMENTS A VACCINATION POLICY FOR TEAM MEMBERS September 10, 2021 |

| Because of the essential products we make – tubing, reinforced hose, and Single-Use tubing assemblies being used in vaccine manufacturing – NewAge’s leadership team has enacted a COVID-19 vaccination policy for team members. The goal is to help maintain the health and safety of all team members and their families.

Most team members have received a COVID-19 vaccine. A small percentage have not for various reasons including medical conditions. The company has not mandated the vaccine, as other organizations have, but has instituted procedures to be followed by unvaccinated team members.

|

| MORE VACCINATIONS August 19, 2021 |

| With the resurgence of COVID-19 cases in the U.S. and across the world, there has been more emphasis on getting vaccinated in the media and from healthcare organizations. People – mainly those who are unvaccinated – are getting sick and succumbing to this deadly disease, leaving grief-stricken families and friends in their wake.

While many NewAge team members have received a COVID-19 vaccine, some have not for various reasons. To encourage vaccination for the health of team members, their families, and NewAge Industries as a whole, the company is again offering the COVID-19 vaccine to its unvaccinated employees onsite at its southeastern Pennsylvania headquarters. The event will take place on Friday, August 27.

AdvantaPure tubing is used in vaccine manufacture and in therapeutics (ventilators and other medical devices) to treat COVID-19 patients, and we’re expanding to be able to produce more tubing. See our Expansion update here. |

| MORE STEPS TOWARD NORMALCY July 13, 2021 |

| The majority of NewAge-AdvantaPure team members have been vaccinated against COVID-19, so a group recently got together for a friendly but competitive game of softball after work. It was fun to be around friends and coworkers again in a relaxed, social atmosphere.

|

| VACCINATED AND BACK IN THE OFFICE June 15, 2021 |

| Several of our teams – Manufacturing, Quality, Warehouse, Human Resources, IT – and many other individual team members have worked at our southeastern Pennsylvania headquarters straight through the COVID-19 pandemic. But others whose job responsibilities did not require their physical presence in the building had been working from home.

|

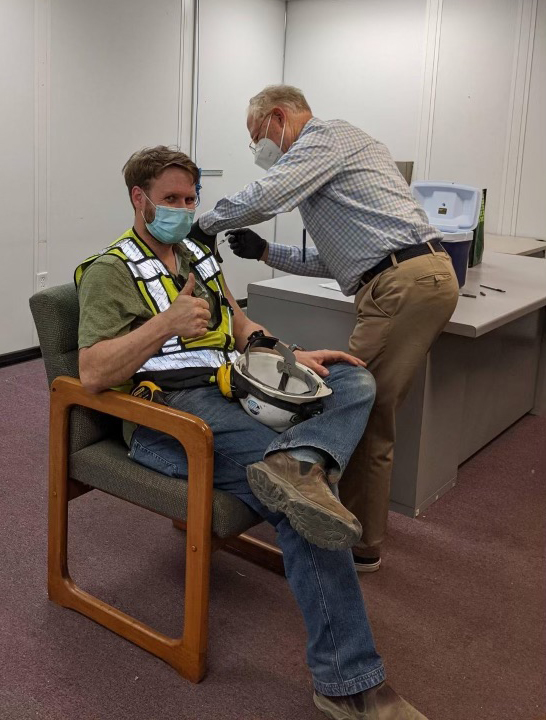

| TEAM MEMBERS AND CONSTRUCTION WORKERS RECEIVE VACCINATIONS May 11, 2021 |

| Pennsylvania, where NewAge Industries is located, had tiered COVID-19 vaccination eligibility guidelines, so while many of our team members were busy making tubing and Single-Use molded assemblies for vaccine development and production, they themselves were not yet eligible to receive the vaccine. Thankfully that changed, and all team members were eligible for and offered the COVID-19 vaccine.

|

| LOCAL CBS NEWS STORY HIGHLIGHTS OUR EFFORTS TO GET COMPANY VACCINATED March 12, 2021 |

| WORKING TOWARD INCREASED MANUFACTURING CAPACITY February 09, 2021 |

It’s a fact: The COVID-19 virus has, in one way or another, affected everyone in the world. Even in the few South Pacific island countries with no reported cases, life has changed. Borders are closed and economies are stalled.

NewAge’s role in the battle against this relentless virus has necessitated adjustments regarding how we conduct business. Many team members not involved with manufacturing, packaging, inspecting, and shipping our silicone, TPE, and plastic tubing products are working remotely. Those who are here are, of course, wearing masks, social distancing, embracing extra cleaning procedures, and keeping sanitary conditions top of mind. All team members are periodically tested for the virus, and many are now on waiting lists for vaccination appointments.

We are fully committed to increasing our manufacturing capacities and improving lead times. Plans have been underway since last year and include:

|